You just cannot disagree with the fact, that India is very near to its population optimum, and with this increasing population the housing requirements have also increased. You cannot ignore that every individual needs housing as a basic amenity. In this article, we shall be discussing how the gen z and Millennial families can choose the Best Sariya for house construction. Besides how the manufacturers are coming up with ways to improve the TMT bar production shall also be discussed. So, stay tuned and keep reading.

The rise in the population can be anything, but basic needs have to be met too! In the following points, we will be explaining to you, how the rise in the volume of the TMT bars is being met by the TMT bar manufacturers and suppliers. So here it goes.

Mass Dicing Technology

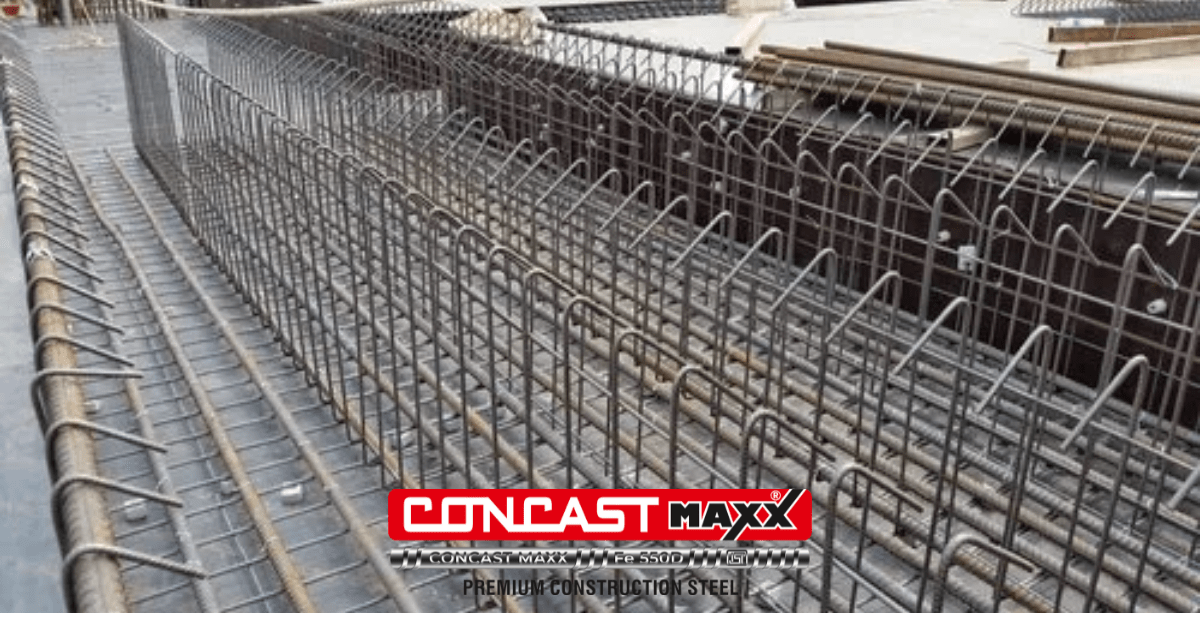

In the mass dicing technology, the TMT bar strands can be produced with enhanced volume. In the individual dicing technology, only one strand of the TMT bar was getting produced. As a result, productivity was low. However, the introduction of the Mass Dicing Technology has eased up the issue and from now on a huge volume of the TMT bars can be produced. Concast Maxx TMT bars being one of the Best TMT bar supplier in Kolkata has been using mass dicing technology for quite a long time and meeting the needs of the ever increasing population.

Mass Gradation Technology

The Best TMT bars are produced from the Concast Maxx pass-through standard gradations. The gradations come in various forms, including Fe500 and Fe550, Fe550D and so on. The gradations protect the construction from seismic waves. With the introduction of Mass Gradation Technology, the number of TMT bars getting has increased. With the introduction of the mass gradation technology the safety quotient in the bars has increased too. The mass gradation technology has infused the appropriate amount of materials that is required for a TMT saria to absorb the earthquake waves.

Improved Quenching Test

The quenching test is mainly used to test the strain-retaining capacity of the bars. The strain-retaining capacity of the TMT bars is based on the results of the quenching test. With the introduction of the quenching test, the number of the TMT bars that undergo this quenching technique has increased as a result the productivity has increased too!! The Top Quality TMT bars produced from the Concast Maxx TMT bars has optimal results from the quenching tests which gets helps the construction get a long life.

Advanced Quality Control

The quality of the TMT bars needs to be assessed and it’s done through proper quality control procedures. Now the problem that arose was how could this be done on a mass scale. The advancement in the procedure of quality control has improved the number of the sarias that could undergo the quality testing. The quality testing is used to check the durability of the TMT bars which help in fixing the adulteration issues.

This was the part of the discussion where the advancement in the procedure was getting shown in the next part we enumerrate some of the criterias which can be followed while choosing the Quality TMT bars for construction. They are as follows-

As a matter of fact we can proudly claim that Concast Maxx qualifies in all the criterias.